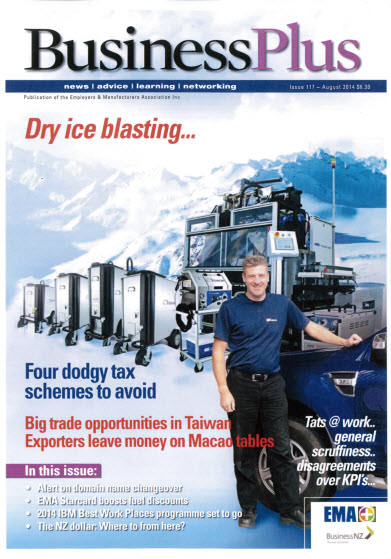

Cool Way to clean

With this technology, natural, non-additive, solid CO² (dry ice) is accelerated at high speed to create a thermal impact that removes contaminants. The dry ice then sublimates, leaving no secondary waste to dispose of. Chief executive Mike Coleman says dry ice has been used globally for more than 25 years as a cleaning solution, and received little attention in New Zealand until now.

He launched Cold Jet New Zealand two-and-a-half years ago after discovering dry ice blasting as a cleaning option for a project he was working on. “I was restoring a classic car, and looking online for a way to remove the underseal and generally clean the underside of the car,” he says.

He launched Cold Jet New Zealand two-and-a-half years ago after discovering dry ice blasting as a cleaning option for a project he was working on. “I was restoring a classic car, and looking online for a way to remove the underseal and generally clean the underside of the car,” he says.

“I came across a method of using a dry ice blasting machine and thought it would not only be the perfect solution to my problem, but also an excellent business opportunity.” After researching a number of dry ice lasting manufacturers, Coleman decided to go with Cold Jet. He visited the company’s global headquarters in the US with a proposal to set up a New Zealand subsidiary.

Cold Jet NZ now runs a six-day-a week dry ice production and delivery service. It makes dry ice at its Wiri factory using liquid carbon dioxide, a by-product of the oil refinery process. Some clients regularly purchase bulk quantities for transporting perishable goods around the country and the world. “We can supply the dry ice in several different formats according to customers’ needs, from 3mm pellets and 16mm nuggets to 5kg blocks.”

Its contract cleaning division is taking off, and volumes of dry ice are increasing to meet demand. Cold Jet New Zealand now provides the full range of dry ice blasting and dry ice production machines, and sells, supports and services its dry ice cleaning systems, nozzles and accessories so customers can carry out their own blasting as frequently as they need to.

Dry ice blasting technology is being used in industries as diverse as food & beverage, medical, plastics, printing and construction. “Not only is it a greener option, but dry ice blasting is also an extremely versatile cleaning method, and I’m discovering new ones all the time.” Recently he used dry ice to help restore headstones at the Symonds St Cemetery after they were sprayed with graffiti.

Abrasive media such as sand, bead and soda blasting grind the surfaces being cleaning and frequently this damages them, Coleman says. “On the one hand, it can be used to remove layers of bitumen from plant and machinery or built-up ink from printing machines or to decontaminate food processing equipment from salmonella, e-coli and listeria, and yet it’s gentle and precise enough to restore smoke damaged books or even remove the lettering on a business card.” “By using technologies like ours, they can demonstrate that they’re taking steps to minimise the impact of their operations on the planet. We can only see our business growing as a result.”