Dry Ice Blasting – How does it work?

Environmentally friendly cleaning and surface preparation

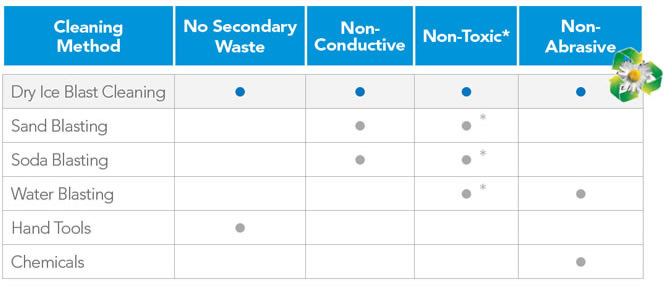

Dry ice cleaning utilizes a unique combination of forces to powerfully lift surface contaminants without causing damage or creating harmful secondary waste. Similar to sand, bead and soda blasting, dry ice cleaning prepares and cleans surfaces using a medium accelerated in a pressurized air stream. But that’s where the similarities end.

Instead of abrasive media to grind surfaces (and sometimes damage them), Cold Jet uses dry ice (solid CO² with a low temperature of -79°C / -109°F), a medium that is natural and non-additive, accelerated at supersonic speeds to create thermal impact that lifts contaminants from substrates. The CO² then sublimates (vanishing into thin air), leaving no secondary waste. This method cleans items that previously seemed impossible, in a very environmentally friendly way.

From gently restoring smoke damaged books, to cleaning multi-million dollar production equipment in place, Cold Jet’s range of dry ice cleaning systems, nozzles & accessories offer robust solutions to meet your toughest cleaning challenges head on.

Instead of abrasive media to grind surfaces (and damage them), Cold Jet uses dry ice (Solid CO2) accelerated at supersonic speeds that sublinate upon impact and lift contaminants from substrates.

Less time. Less effort. Less money.

Traditional cleaning methods usually require a hammer, chisel, scraper, hazardous chemicals and significant labour—turning a minor preventative maintenance effort into a major disruption. Dry ice cleaning from Cold Jet offers comprehensive cleaning benefits over traditional methods, and can save up to 80 percent over current cleaning costs and provide a return on investment (ROI) in as few as three months. Our method improves productivity and profit as cleanup that was once managed in hours or days can now be done in minutes. Most equipment can be cleaned in-place with no disassembly or cool down required. We are able to produce custom solutions for any budget.

*Upon contact, traditional blasting materials become contaminated when used to clean hazardous substances and objects. These blasting materials are also then classified as toxic waste and require appropriate safe disposal.