Keep the lines running with mould cleaning made easy

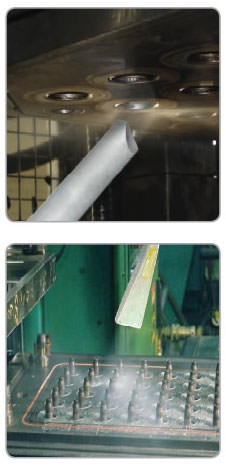

A major problem faced by rubber moulders is mold fouling. Build-up of cured material and mold release agents causes sticking moulds, blemishes and unwanted flash on final parts, making them unusable and requiring line shutdown for cleaning.

Traditional cleaning methods such as manual scraping, glass bead blasting or ultrasonic cleaning can be time consuming, ineffective, damaging to moulds and result in high labour and material costs. Dry ice blast cleaning offers an in-place, online, quick and effective way to clean without damaging expensive moulds.

Applications

- Injection moulding

- Blow moulding

- Compression moulding

- Tilt-back press

- Lift press

- Metal boned mould

Key Benefits

- Eliminate production shutdown; clean online, no cool down required

- No disassembly of moulds; eliminate reassembly damage and scrap

- Reduce product scrap; no more delayed cleaning resulting in product defects

- Non-abrasive; no impact damage or mould erosion

- Increase production time; 25-50%

- Reduce cleaning time; labour cost reduction up to 75%

- Environmentally responsible; no secondary waste

Tell us about your specific cleaning needs – contact us today