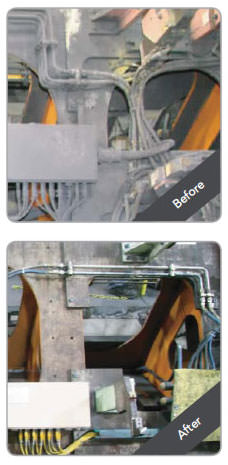

Better Welds = Less Scrap and Downtime

Weld slag, spatter, resin, smoke, oil and dampering adhesive builds up on production equipment. This causes misalignment and can prevent the proximity switch from firing in the appropriate spot. The robot stops welding, or welds incorrectly creating scrap and causing equipment failure and production downtime.

“No contact” dry ice blast cleaning provides an effective and economical removal solution for slag and spatter build up.

Applications

- Robot joints

- Transfer cases

- Shuttle jigs

- Diamond plates

- Trunnions

- Weld tables

- Fixtures

Key Benefits

- Reduce scrap rates

- Reduce fixture repair

- Reduce replacement costs

- Environmentally responsible

- Minimise downtime

- Maximise tolling life

- No secondary waste

- Non-abrasive, won’t damage sensors

- Clean online, no cool down required

- Replaces ineffective and costly labour

- Intensive cleaning methods

Tell us about your specific cleaning needs – contact us today